A LP Gas Industrial gas practitioner (installer) is ONLY licensed to carry out installations as per SANS10087 part 3.

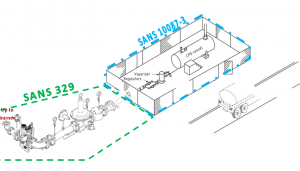

This part specifies requirements for the installation of liquefied petroleum gas equipment, and of storage vessels and associated vaporizers, pipework and fittings up to the outlet of the first pressure reduction stage in the line. Any installation downstream of the outlet needs to comply with SANS 329 and is a separate qualification, competency and registration criteria with the Southern African Gas Association only.

SANS329, is the thermorocessing standard applicable to the safety requirements for combustion and fuel handling systems used in Industrial Thermoprocessing Installations. It also applies to the handling of fuel immediately adjacent to the equipment but downstream of, and including, the main plant fuel shut-off valve.

Schematic design SANS 10087-3 vs. SANS 329

Industrial Thermoprocessing Gas Practitioner Category Registration . . .as per SANS 329

- Design of a Combustion System – Design, layout and planning of the combustion system inclusive of the gas and electrical systems.

- Build reticulation pipelines <2 Bar – Building of pipelines or the modification of pipelines which operates at a pressure smaller than 2 Bar gauge pressure.

- Build reticulation pipelines <15 Bar – Building of pipelines or the modification of pipelines which operates at a pressure between 2 and 15 Bar gauge pressure and is normally in the distribution environment

- Installation of Combustion Equipment – Installation and/or modification of combustion equipment which operates in industrial areas. Example thermoprocessing equipment.

- Maintenance of Combustion Equipment – Maintaining all thermoprocessing equipment. When any maintenance is performed on a gas system such as the cleaning of an inline filter, removal of a valve and the replacement of any thermoprocessing equipment.

- Commissioning of gas systems and equipment – Commissioning of the total thermoprocessing system from the ball valve to the respective burners of installed equipment after being pressure tested and providing a Certificate of Conformance confirming the gas system and equipment is safe and fit for purpose. When a newly built / installed system is to be put into operation the commissioning of such a system will include the entire thermo-processing system, and will require the verification of the all the safety devices and controls on such a system. Commissioning can only be conducted by a competent commissioning gas practitioner.

- Re-Commissioning of gas systems and equipment – When equipment is replaced and the system restarted after maintenance or modifications has been done the system needs to be recommissioned by a competent gas practitioner duly appointed by management after being pressure tested and providing a Certificate of Conformance confirming the gas system and equipment is safe and fit for purpose.